How does coffee get from the seeds to your coffee pot...

The berries are picked and harvested every

year during the dry season, sometimes more than once a year

depending on climate and location of the plants. There are two

methods to process the ripe cherries, wet method (mostly done in

As soon as the crimson “cherries” appear, they are either hand selected, leaving the non-ripe berries to continue growth, or collected using a harvesting machine which picks all the berries, ripe or not. Using a harvesting machine decreases production because all the berries are picked.

If the stripping method is used, the ripe berries need to be separated from the non-ripe and other debris that tends to float, while the ripe cherries sink. Next, the cherries are either dried using the natural drying method or sent to coffee pulping machines following the wet method process. The pulping machines remove the ripe red fruit away leaving only the green beans. While in the drying method, the whole cherry ferments.

When just the green beans remain they are

covered in a slippery substance and added to cement tanks with

water and sent to fermentation tanks where they will ferment for

16-36 hrs to remove that mucilage layer. When that layer is

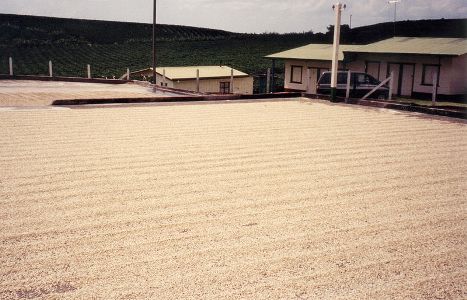

gone, the beans are spread out to dry on patios just as they do

in the dry method.

The natural dry method is the oldest, simplest method. It takes place in countries where rainfall is low and there is lots of sun to dry the coffee correctly. This process is fermentation of the whole fruit. The berries are spread on the patios in 10cm thick layers, and re-spread each day totaling 10-25 days of drying. During this time is when microbial fermentation takes place and has the potential to influence the production quality as stated on the Interactions/Adaptations page.

After the drying process, the coffee is roasted (a chemical process) to alter the flavor, aroma, and acidity depending on the roaster used in the process. The beans go through a series of reaction processes that start when the temperature reaches 205° C and is completed when the temperature has reached 230° C. The beans change from a light green color to a medium-dark brown with an oily appearance by the end of roasting. They also go through a series of cracks in the beans that mark certain changes during the chemical processes. Acidity, bitterness, sweetness, and aroma are altered during roasting to differentiate coffee blends and the process is stopped somewhere in between the range of temperatures and associated cracks for the desired product.

The final step after roasting is brewing a sample of the coffee to determine the quality in the cup before it is packaged, shipped, and brought to a store near you.